(How to correctly choose CNC machining equipment?)1.Processing accuracy: Choose CNC equipment with appropriate precision to meet the dimensional requirements of the parts being processed.2.Working range and size: The equipment's working range should meet the size requirements...

(How to correctly choose CNC machining equipment?)

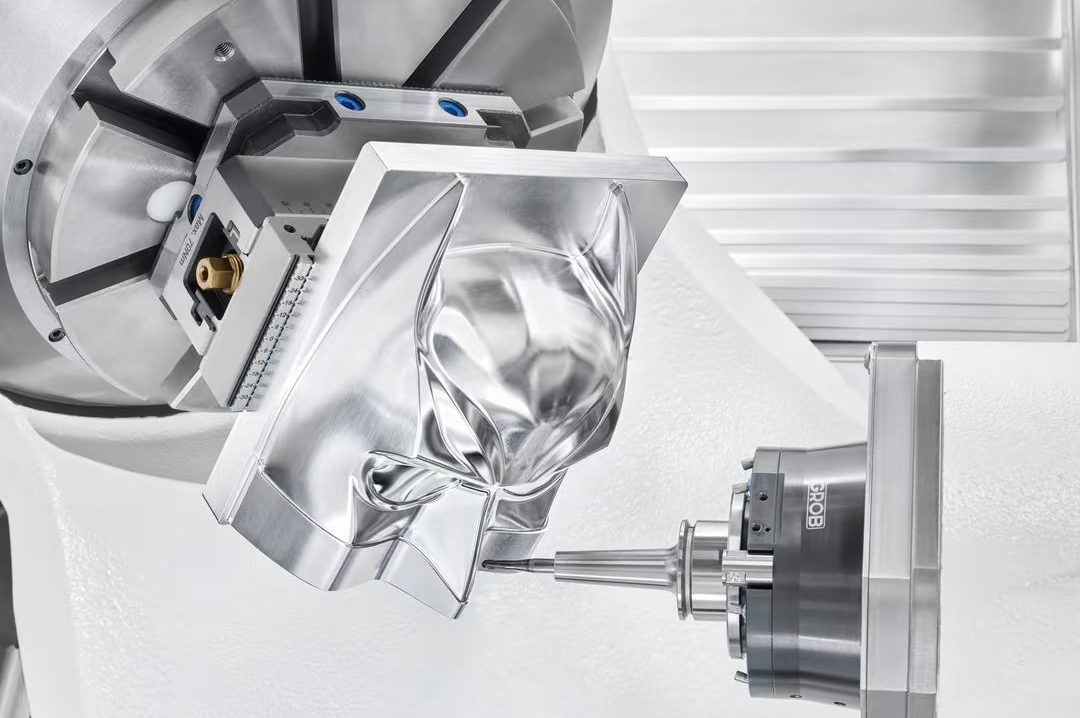

1.Processing accuracy: Choose CNC equipment with appropriate precision to meet the dimensional requirements of the parts being processed.

2.Working range and size: The equipment's working range should meet the size requirements of the largest parts to be processed.

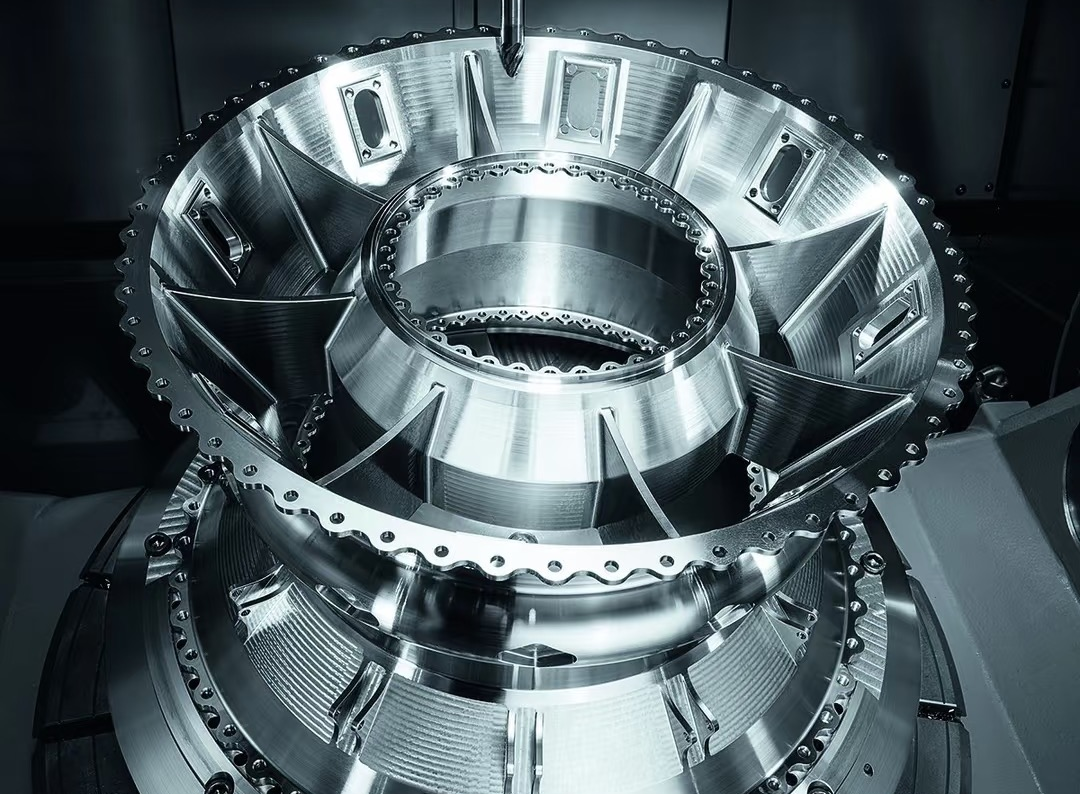

3.Production efficiency: Choose the right equipment based on production scale; some equipment is suitable for efficient mass production, while others are better for low-volume or custom production.

What are the advantages of cnc machining

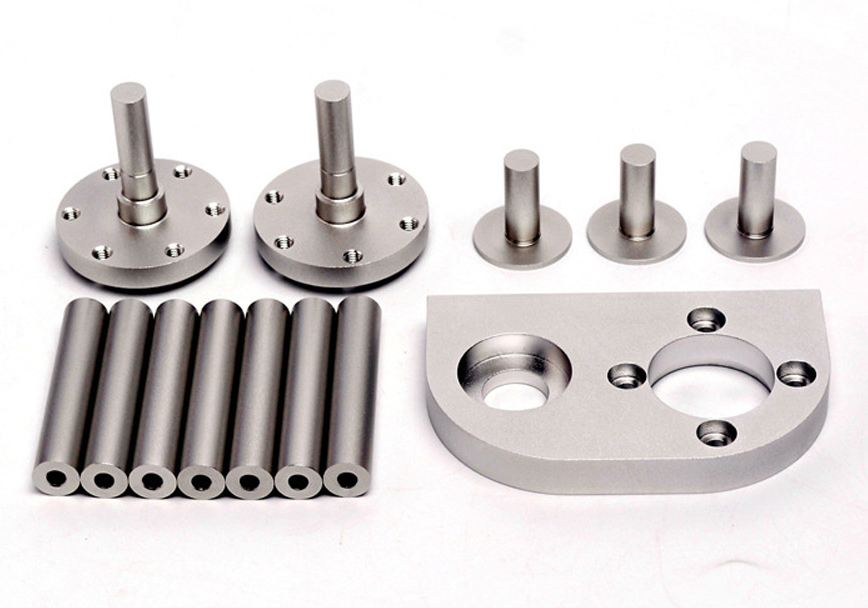

1.No MOQ:CNC machined parts have no minimum order quantity or minimum purchase quantity. This means that we can efficiently manufacture small batches or even one-off custom parts at a relatively low cost.

2.High Material Utilization:CNC machining allows for precise cutting and shaping, reducing material waste and improving material utilization.

3.Labor Cost Reduction:Due to the automation of CNC machines, there is a significant reduction in labor dependency, which lowers labor costs.